When green coffee arrives at our Topeka warehouse, the next step is not so simple as throwing it in a roaster and bagging it up to sell. From sample roasting to profile developments to production roasts, we have various roasting tools at our disposal to explore each coffee’s potential and determine the best way to roast it.

Ever wondered what kind of machines we use for our roasting process, and why? To satisfy your curiosity, we tasked ourselves this week to gather knowledge on that topic and more. The best way to accomplish this was asking our Head Roaster, Mike Mazulo.

Dive into our Q&A below to learn the ins and outs of the roasting process at PT’s:

Q: What machines do you use at PT’s Coffee Roasting Co.?

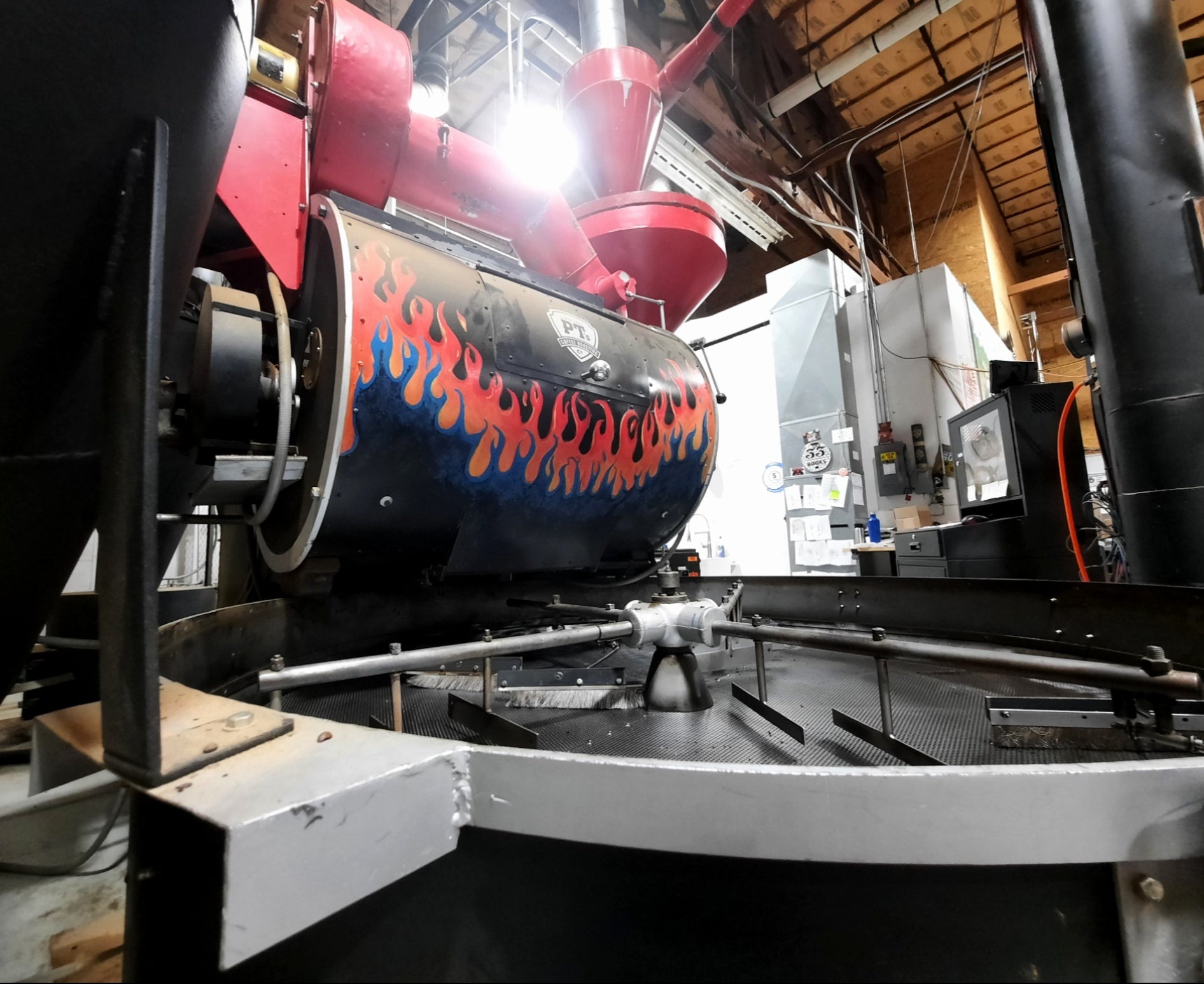

Mike: We use two Diedrichs—one IR-24 and the other is a IR-5—along with a German Gothot and our sample roaster is a Marty Curtis Primo.

Q: When were they built roughly?

Mike: Our red IR-24 was built in the early 2000s. Black IR-5 in 2014. The Gothot in 1932. The sample roaster, late 90’s.

Q: How much coffee can each machine roast?

Mike: The Gothot roasts upwards of 180 pounds. The IR-24 roasts at a max capacity of 52, but we keep it to 30-46 pounds, while the IR-5 can do up to 12 but we keep it to 2-8 pound batches. (This helps us retain more control over the roast.) The sample roaster only does 100 grams per roast.

Q: What are each of them used for?

Mike: The Gothot is used to roast the components of our post-roast Signature Blends (think John Brown, Southpaw, Flying Monkey, Flor Del Sol, etc.). Our IR-24 is mostly used for production of our staple Single-Origin offerings. The IR-5 is used in coffee profile developments, along with small-batch Blue Label or Single-Origin offerings. The Primo is used for purchased offerings and then we also use it for pre-ship samplings and arrival sampling.

Q: How often are each of them used and tended to?

Mike: We use the Gothot and IR-24 every day. The IR-5 is used a couple days a week for new profile developments and every Tuesday for our Blue Label microlot offerings. Primo is used as needed, varying on samples arriving from origin.

Q: What is it like to roast on these machines?

Mike: Every machine has its own dynamics and each has its own attributes, with the Gothot being a convection roaster and the others conduction. Keeping the roast profile characteristics the same with different styles and different roasting behavior is definitely a fun challenge.

Q: Do you have any other experience with other machines?

Mike: Yes, almost every other machine: Mill City, Giesen, Probat, Loring, US Roaster Corp, Joper, and Ikawa.

Q: Are they manual or automated?

Mike: The Diedrichs are fully manual roasters, while the Gothot is automated with manual controls and finally the Primo is fully manual. Same for our up and coming Probat sample roaster.

Q: Can you explain the difference between roasts and what it takes to get there?

Mike: Let me answer that one with a question: What is a roast? It’s the controlling of heat and air (and in case of our Gothot, drum speed) to reach a temperature of set points in a desired time to achieve certain flavor characteristics and qualities optimal to PT’s desired outcome.

Q: What are the glories of being a roaster?

Mike: It’s not all it’s cracked up to be. Behind the glory shots and videos people post on social media, it’s a lot of burning yourself, throwing your back out over throwing heavy bags of beans, sweating non-stop, and restacking pallets, scraping and cleaning the chaff box and flues, among other things. Definitely gives the saying “blood, sweat, and tears” a new meaning when roasting.

In regards to the glories of roasting it is tasting the finished product that achieves the desired characteristics and attributes that we aimed for in the final reputable product. Being able to know how to approach a brew by knowing how it roasted for the bean and process applied.

Also, opening the vac-seal bags cuz that’s super fun!