In the previous few courses of our Roasting Science direction, we’ve been exploring the evaporation entrance that bureaucracy within espresso beans as they roast. In espresso roasting this phenomenon has a virtually legendary standing. It has even been touted as a conceivable reason for first crack, however there’s little or no direct learn about in this matter, and quite a lot of conjecture.

On this submit, we’ll take a better take a look at what we do find out about how moisture evaporates right through roasting, and give an explanation for one of the the reason why evaporation is so vital to how the espresso roasts.

When Does the Moisture Evaporate?

Sadly, it’s very onerous to as it should be measure what occurs to the moisture within the bean right through the roast. There are necessarily two approaches: both take out samples of beans at more than a few levels right through the roast, and measure the remainder moisture content material within the pattern; or measure the moisture being given off within the exhaust gases.

Each and every manner comes with issues: if you’re measuring the water content material of samples from the roaster, they must be cooled first, right through which era they might proceed freeing moisture, or soak up it from the air. To measure the moisture content material with a dehydration oven — essentially the most correct manner — the beans might wish to be flooring, at which level they will free up extra moisture or different gases that may have an effect on the end result (Schenker 2000).

The opposite manner, measuring the moisture within the exhaust stack, is technically lovely difficult. It additionally makes it onerous to differentiate between present moisture within the bean being evaporated, and additional moisture this is created in chemical reactions right through roasting.

James Davison, a chemical engineer and founding father of Williamstown Roasters, took the second one way to measure the moisture given off through beans right through roasting. In his effects, proven within the graph beneath proper, the overall quantity of water launched makes up about 16% of the preliminary weight of inexperienced beans — however an excessive amount of the water that he detected would had been created right through the roast.

The customized anemometer used to measure airflow within the exhaust stack for James Davison’s experiments

The customized anemometer used to measure airflow within the exhaust stack for James Davison’s experiments

All of which means it’s onerous to make sure in regards to the moisture content material within the bean right through roasting, and makes an attempt to measure it ceaselessly give conflicting effects. Alternatively, maximum to be had proof means that moisture is constantly evaporating the entire manner throughout the roast, reasonably than simply right through the so-called ‘drying section’ originally of the roast.

Two approaches to measuring moisture loss. The left-hand graph, tailored from Schenker (2000), presentations the moisture content material of bean samples got rid of at other levels of the roast in a fluid-bed roaster operated at a hard and fast temperature. The proper-hand graph, from Davison (2019) is according to the moisture content material measured within the exhaust gases right through roasting. Those measurements had been taken in a drum roaster, and display a definite spike in moisture evaporation to start with crack. The overall water content material is calculated from the moisture evaporated within the stack and subsequently contains water created in chemical reactions right through roasting.

However this doesn’t imply that the moisture content material is reducing calmly all the way through the bean. As a substitute, for lots of the roast, there’s a transparent separation between a dry area at the out of doors of the bean, and a humid area at the within. Between the 2 is a layer the place moisture is evaporating and escaping from the bean — the evaporation entrance.

The Evaporation Entrance

The core concept of the evaporation entrance is that water has to flee from the out of doors layer of the bean first. At first of the roast, the bean temperature will increase quickest close to the bean floor, and warmth travels extra slowly to the interior layers. The moisture close to the bean floor subsequently evaporates first, making a layer of water vapour within the outer a part of the bean — the evaporation entrance.

Because the bean temperature rises previous 100°C, the strain within the bean starts to upward thrust as steam builds up quicker than it might probably break out. The strain can succeed in as excessive as 25 bars right through the roast (Bonnländer et al 2005) — greater than two times the volume of strain you’ll to find in an Olympic monitor motorcycle tyre. The excessive strain makes it more difficult for water to evaporate, so the bean nonetheless accommodates liquid water, or water sure to the bean construction, at neatly over boiling level. This works in simply the similar manner that the steam boiler for your coffee gadget accommodates each steam and water at 120°C or extra: the strain prevents water from evaporating, which permits the temperature to extend previous the standard boiling temperature.

Within the outer layers of the bean, the steam can break out throughout the bean’s pores, the strain drops, and the remainder water evaporates. Within the inside layers of the bean, the steam can’t break out, as a result of it’s surrounded through excessive strain steam on both sides.

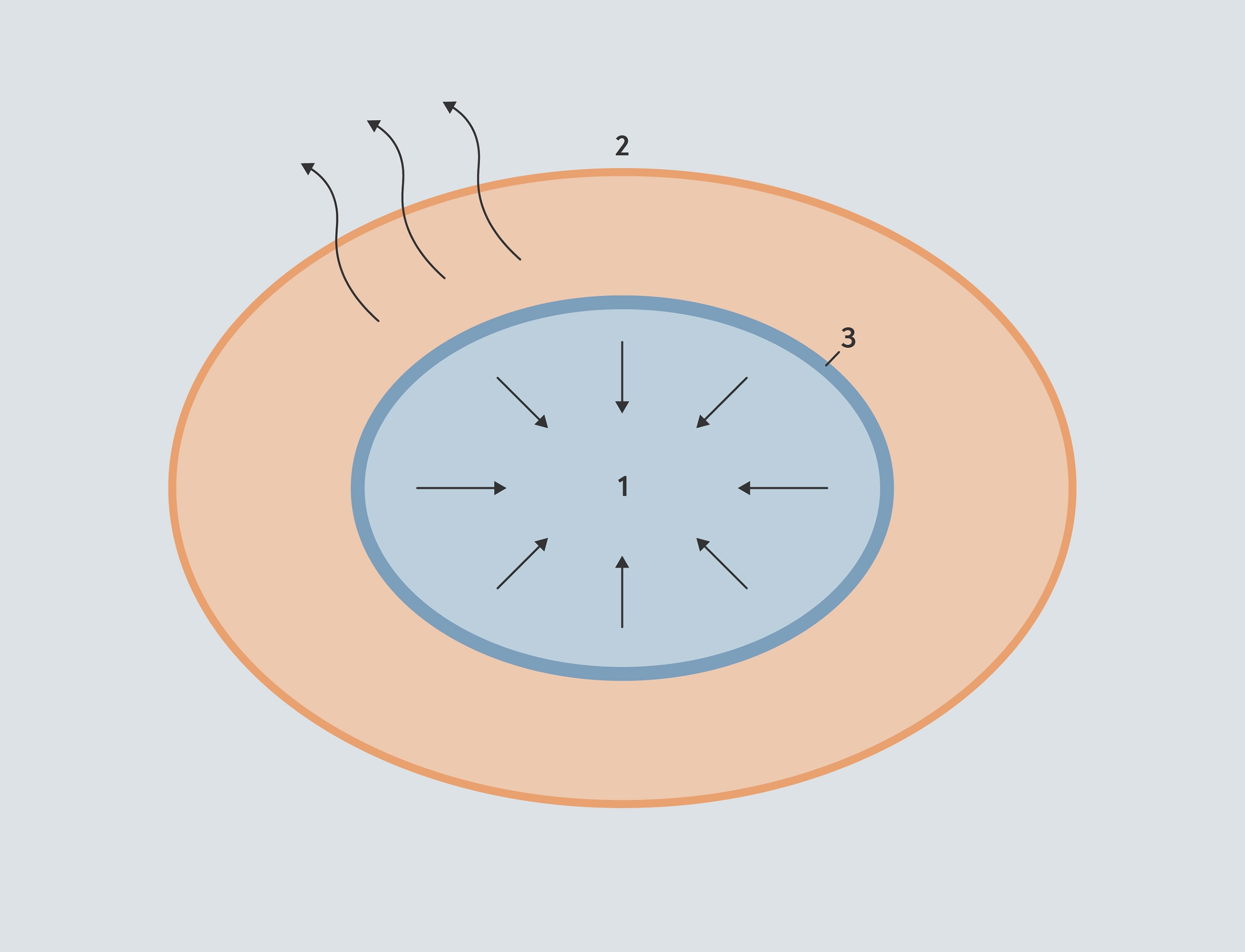

The evaporation entrance. The core of the bean (1) accommodates each liquid/sure water and steam at excessive strain. The steam can’t break out, as a result of it’s surrounded through excessive strain on both sides. Steam escapes from the outer layer of the bean (2). In between the 2 is the layer the place the liquid/sure water is in a position to flip to steam — the evaporation entrance (3).

The evaporation entrance. The core of the bean (1) accommodates each liquid/sure water and steam at excessive strain. The steam can’t break out, as a result of it’s surrounded through excessive strain on both sides. Steam escapes from the outer layer of the bean (2). In between the 2 is the layer the place the liquid/sure water is in a position to flip to steam — the evaporation entrance (3).

The result’s a dry layer at the out of doors of the bean, whilst the centre nonetheless accommodates quite a few moisture. Because the roast continues, the evaporation entrance strikes inwards in opposition to the centre of the bean as an increasing number of of the steam escapes the bean.

The Significance of Evaporation

Turning water into steam takes a large number of power — the power required is named the latent warmth of vaporisation. Figuring out that is key to working out how moisture evaporating impacts the best way beans reply to warmth within the roaster.

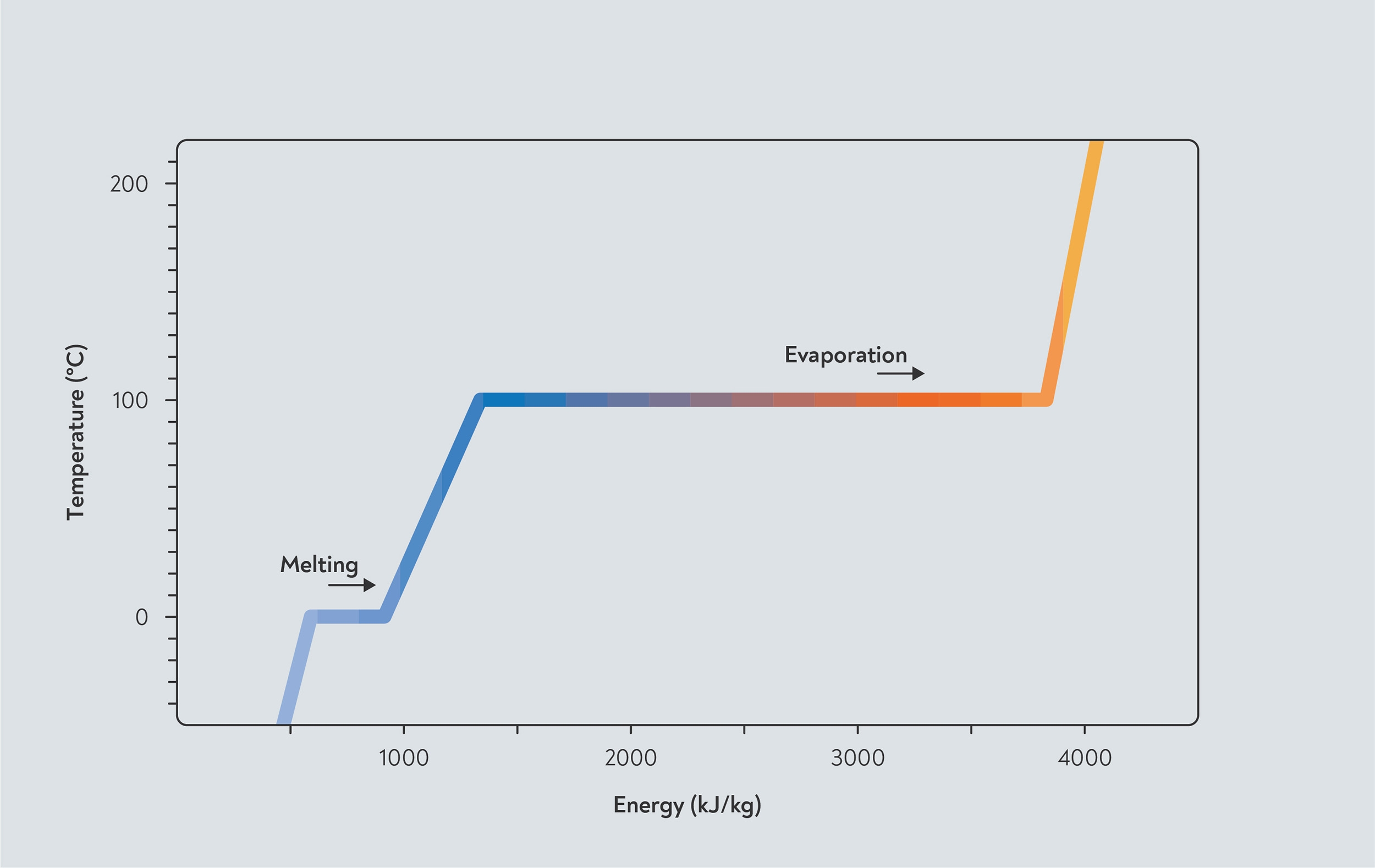

Should you warmth water at a hard and fast charge, the temperature of the water regularly will increase. Alternatively, at 100°C, one thing odd occurs. You stay making use of warmth, however the temperature stops expanding and the water remains at 100°C. That power is now going in opposition to turning water into steam, as a substitute of accelerating the temperature of the water. Actually, it takes 5 occasions as a lot power to show water into steam because it does to warmth water from 0 to 100°C.

The latent warmth of vaporisation of water. As you upload warmth, the temperature of water will increase as much as the 100°C however then stops. Any more warmth added is used for evaporation, till the entire water has grew to become to steam.

The latent warmth of vaporisation of water. As you upload warmth, the temperature of water will increase as much as the 100°C however then stops. Any more warmth added is used for evaporation, till the entire water has grew to become to steam.

Because of this on the evaporation entrance, a large number of the power absorbed through the bean goes into vaporising the water, as a substitute of into expanding the temperature. Within the outer layer of the bean, then again, that warmth can all move into riding chemical reactions and lengthening the temperature of the bean.

The impact of that is that any warmth that penetrates the bean is in a position to build up the temperature of the outer layer quicker than the interior layer.

Boundaries to Warmth

Because the roast progresses, the outer layer additionally begins to behave as a barrier, decreasing the volume of warmth attaining the centre of the bean. At the start, the outer layer dries out. Dry espresso conducts warmth much less neatly than wet espresso, so the dry outer layer acts as an extra barrier to warmth attaining the centre. Secondly, the outer layer begins to change into extra porous because the cellular construction breaks down. The pores are insulating, as a result of they’re full of gasoline — simply recall to mind how expanded polystyrene works. The result’s that the higher quantity of pores make the outer layer even much less efficient at accomplishing warmth to the centre.

Because the outer, dry, layer is much less excellent at accomplishing warmth into the bean, a temperature gradient begins to increase, with the bean floor being freshest. The core of the bean, the place the construction remains to be wet and dense, is more practical at accomplishing warmth. Any warmth that reaches this zone is transferred to the core extra simply, so the temperature inside the core of the bean is extra homogeneous.

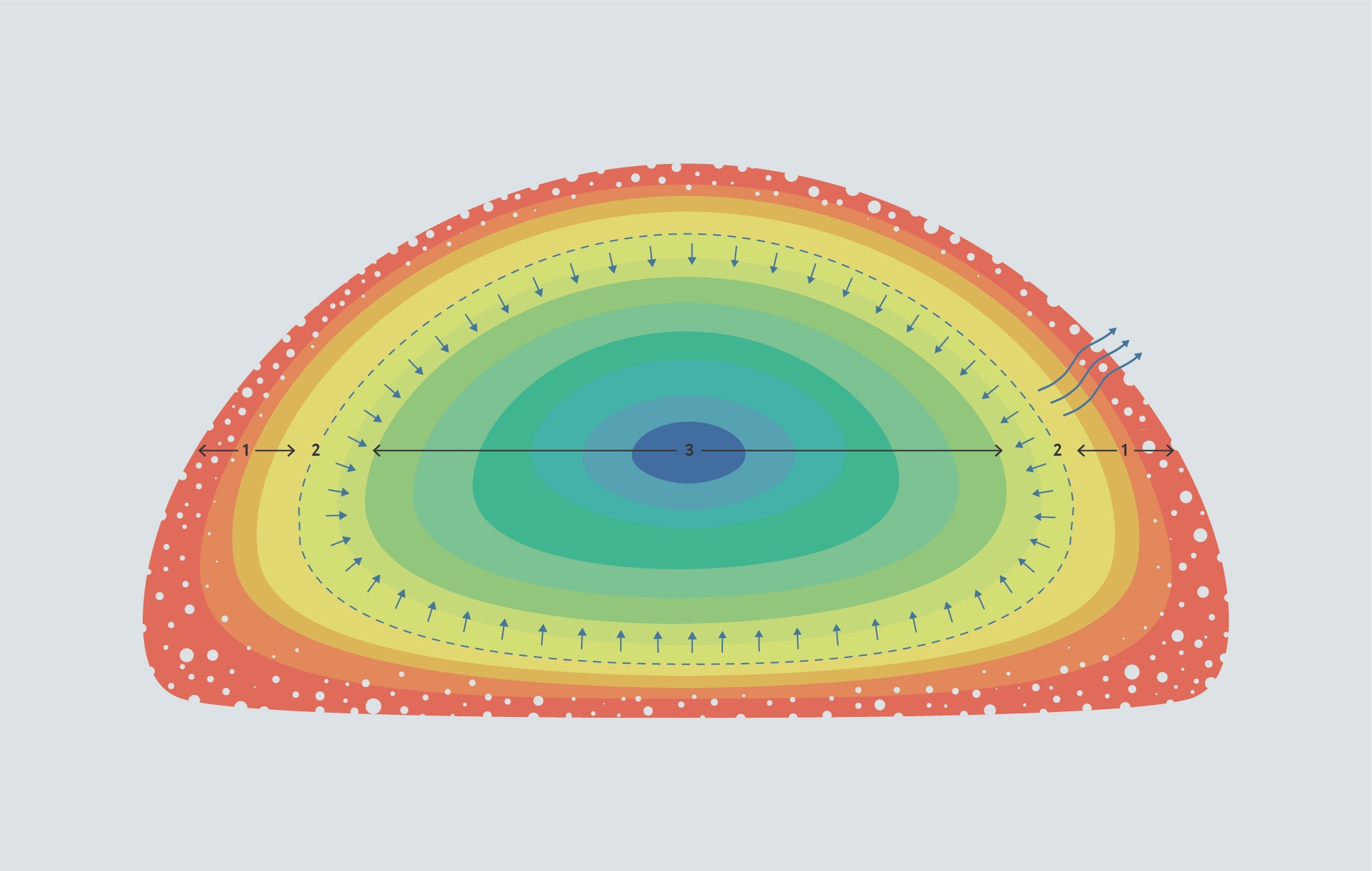

The evaporation entrance prevents warmth from attaining the centre of the bean. Within the outer layer of the bean (1), the bean construction is expanded and porous and the moisture content material is low, so it doesn’t habits warmth successfully to the interior layers. This ends up in a steep temperature gradient between the out of doors and the interior of the bean. On the evaporation entrance (2), moisture is soaking up warmth and changing into steam. The centre of the bean (3), which is denser and has the next moisture content material than the outside, conducts warmth extra successfully than the outside, so the centre has a extra homogeneous temperature

The evaporation entrance prevents warmth from attaining the centre of the bean. Within the outer layer of the bean (1), the bean construction is expanded and porous and the moisture content material is low, so it doesn’t habits warmth successfully to the interior layers. This ends up in a steep temperature gradient between the out of doors and the interior of the bean. On the evaporation entrance (2), moisture is soaking up warmth and changing into steam. The centre of the bean (3), which is denser and has the next moisture content material than the outside, conducts warmth extra successfully than the outside, so the centre has a extra homogeneous temperature

Modelling the Evaporation Entrance

We will’t see the evaporation entrance at once — we handiest surmise it’s there as a result of that is how drying behaves in different fabrics. Alternatively, we will be able to expect what occurs through the use of mathematical modelling. In a chain of papers, researchers on the College of Oxford and Jacobs Douwe Egberts constructed a mathematical type to explain the behaviour of moisture within the bean right through roasting.

They discovered that their type predicted two very distinct zones within the bean: a high-pressure zone within the centre, proceeding each steam and liquid or sure water, and a definite zone on the fringe of the bean that was once totally dry — with a slim evaporation entrance between them (Fadai et al 2016).

The evaporation entrance, as predicted through modelling. Area i accommodates steam and liquid/sure water at excessive strain, and regularly shrinks because the evaporation entrance strikes inwards. Area ii is totally dry. Tailored from Fadai et al (2016)

The evaporation entrance, as predicted through modelling. Area i accommodates steam and liquid/sure water at excessive strain, and regularly shrinks because the evaporation entrance strikes inwards. Area ii is totally dry. Tailored from Fadai et al (2016)

Strangely, their type means that the temperature is just about the similar all the way through the entire bean. This would indicate that the impact of the evaporation entrance on warmth switch is quite small, and that the best way that moisture escapes from the bean is extra vital to figuring out how a espresso roasts than how simply warmth penetrates to the centre.

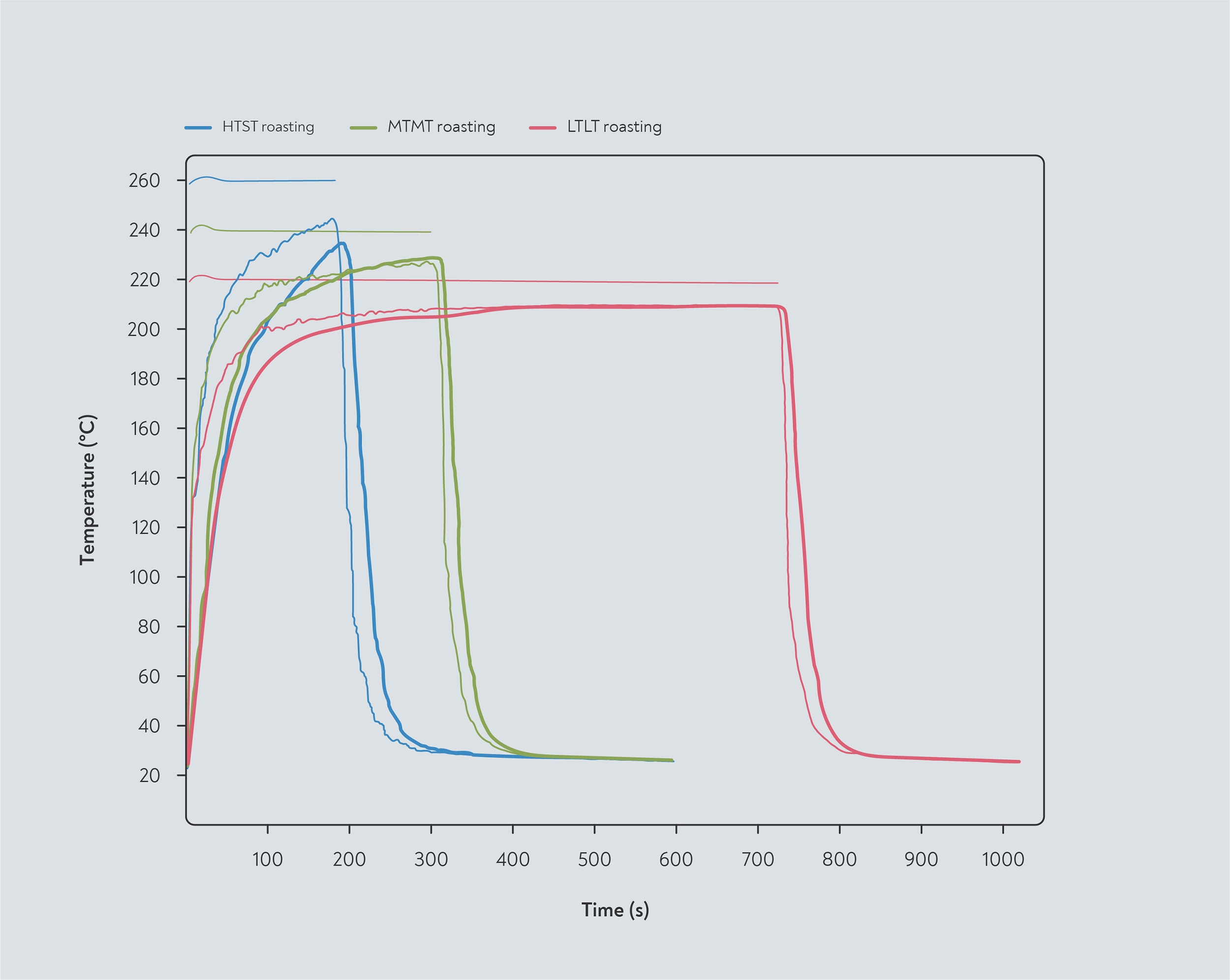

The temperature distinction between the centre and the outside of the bean in all probability will depend on the roasting stipulations. Schenker (2000) inserted a tiny temperature probe right into a bean with the intention to measure the variation between the temperature within the bean and the temperature of the bean pile, as given through the ‘bean temperature’ probe. How carefully the temperature of the core and the bean pile aligned depended at the total roast pace — quicker, warmer roasts confirmed a larger distinction whilst within the slower roast, the bean core temperature stuck up with the bean pile temperature round half-way throughout the roast.

Temperature of the bean pile and bean core right through roasting in a fluid-bed roaster running at fastened temperatures. The bean core temperature lags at the back of the bean pile however in the end catches up within the slower roast. 3 profiles had been used: excessive temperature, couple of minutes (HTST); medium temperature, medium time (MTMT); and coffee temperature, very long time (LTLT). Tailored from Schenker (2000)

Temperature of the bean pile and bean core right through roasting in a fluid-bed roaster running at fastened temperatures. The bean core temperature lags at the back of the bean pile however in the end catches up within the slower roast. 3 profiles had been used: excessive temperature, couple of minutes (HTST); medium temperature, medium time (MTMT); and coffee temperature, very long time (LTLT). Tailored from Schenker (2000)

The Evaporation Entrance and First Crack

The evaporation entrance has one different vital impact. Because the temperature of the bean will increase, someday the bean subject matter undergoes a transition from a rubbery state to a brittle one — referred to as the glass transition. The temperature this occurs at will depend on the volume of moisture — if there’s extra moisture, the glass transition occurs at a decrease temperature.

Incorporating this into the type of the evaporation entrance has a captivating impact: at a undeniable temperature, the core of the bean undergoes the glass transition because it has extra moisture, and turns into rubbery and ready to enlarge with the increase of steam strain. The outer layer of the bean, then again, stays brittle as a result of it’s dryer, and so resists that growth. Because the bean temperature will increase, rigidity builds up as the interior area tries to swell however is contained through the brittle outer layer. This rigidity might be the reason for first crack (Fadai et al 2019).

Getting a greater working out of the way moisture escapes from the bean might end up to provide an explanation for much more about espresso roasting than we up to now idea. If the strain created between the interior and outer layers of the beans is the reason for first crack, then editing how moisture escapes from the bean, or controlling when the glass transition takes position within the other layers of the espresso, may have profound implications for controlling the entire roast profile.